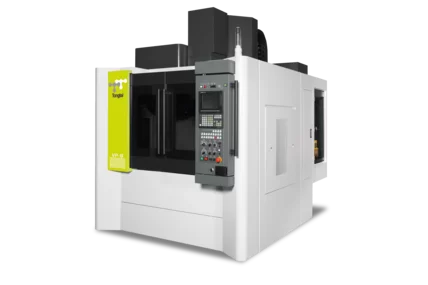

GT series

Vertical 5-axis gantry machining center

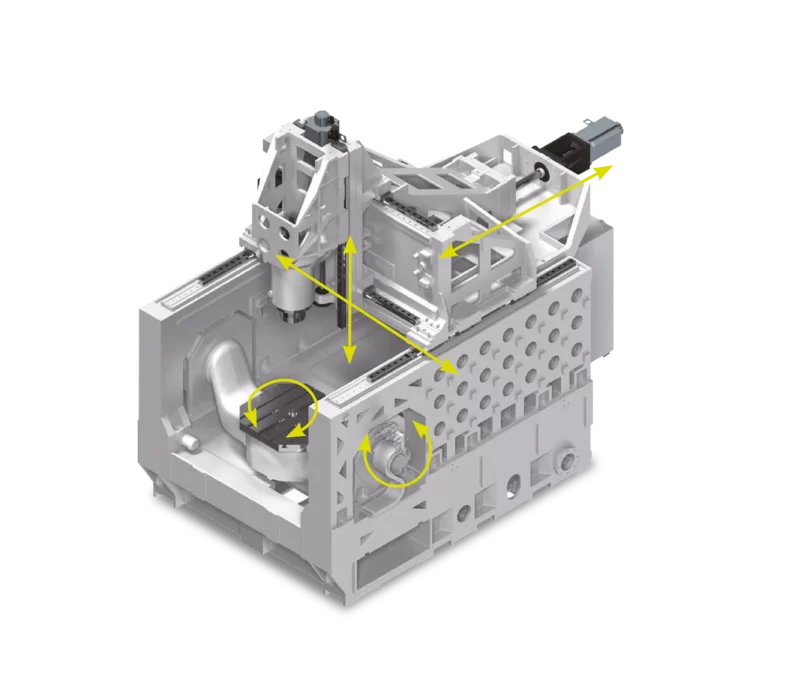

The GT series is a 5-axis machining center in gantry design, developed for the simultaneous machining of complex workpieces in the aerospace, mould making and automotive industries. Its dynamic structure, backlash-free swivel axes and optimized power flow between the spindle and axes ensure high dimensional accuracy, surface quality and process reliability, even during high-speed machining.

Technical details:

| Machine model | GT-500 | GT-630(f) | GT-800E |

|---|---|---|---|

| Number of axles | 5 | ||

| X/Y/Z travel [mm] | 610/610/510 | 760/820/560 | 800/820/560 |

| X/Y/Z feed [m/min] | 48/48/48 | ||

| Max. Table load [kg] | 400 | 600 | 800 |

| Maximum component size [mm] | ø600/400 | ø800/500 | ø900/500 |

| Tool holder | BBT-40 | ||

| Tool capacity | 32(40) | 32 (40; 64;80) | |

| Controls | Siemens, Heidenhain | ||

Typical components

The GT series is suitable for machining blisks, blades, impellers, engine housings, mold inserts and precision parts made of aluminum, steel or titanium. Ideal for simultaneous 5-axis milling, high-speed and finishing machining