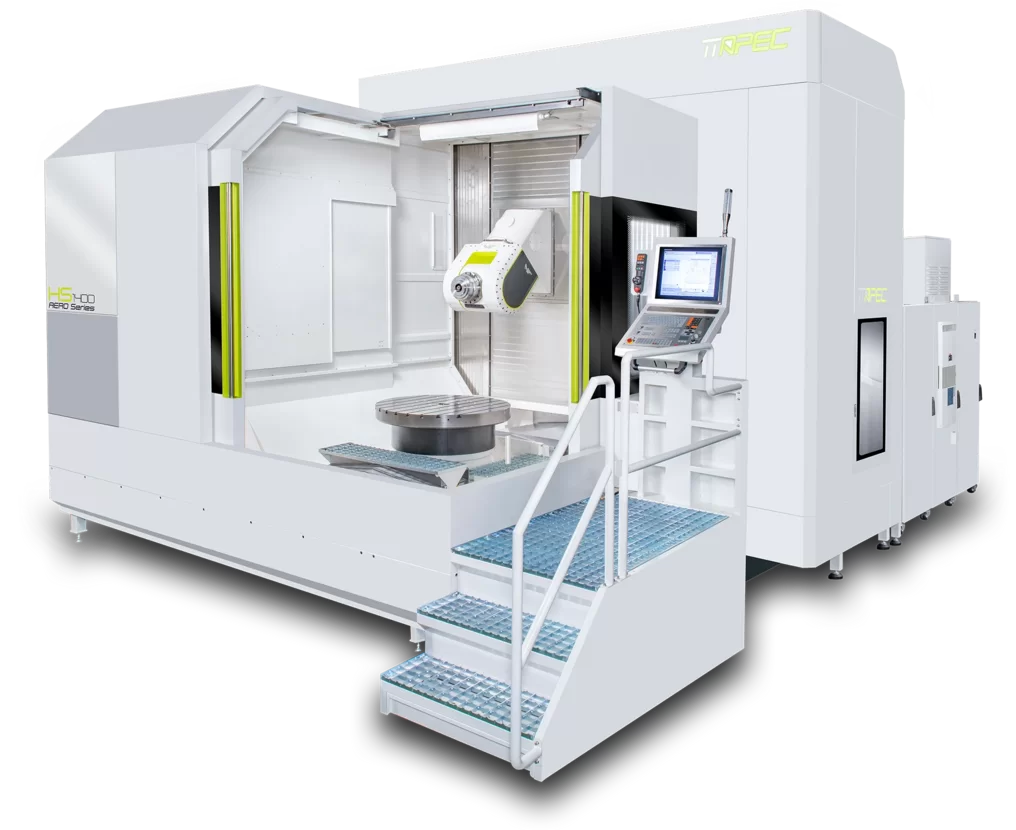

HS series

5-axis horizontal machining center

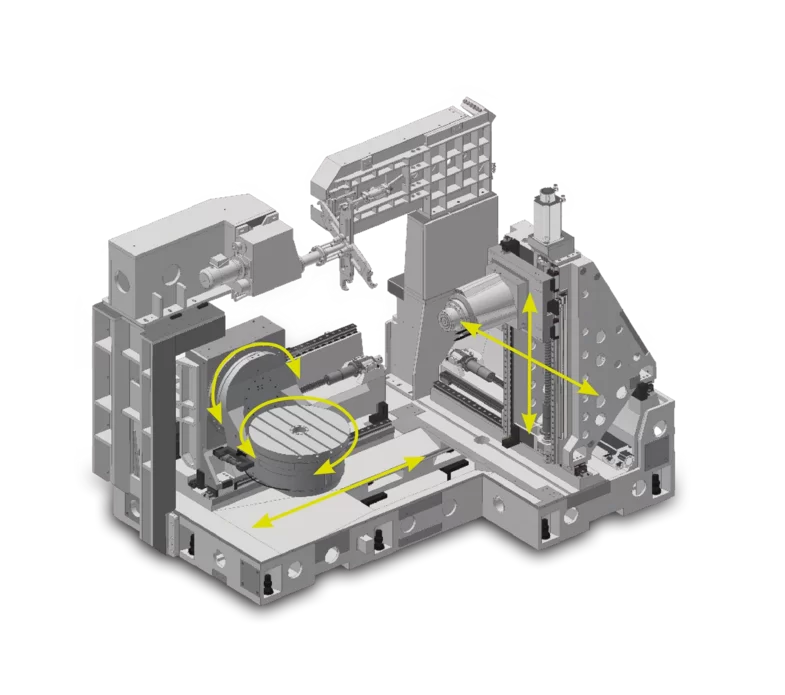

The HS series is designed for simultaneous 5-axis machining of large and complex structural parts in the aerospace industry. Its highly rigid machine structure, the double ball screw guide on all axes and the direct drives on the swivel axes guarantee maximum precision, high cutting performance and process reliability, even when machining difficult-to-cut superalloys.

Technical details:

| Machine model | HS700 | HS1400 | HS1400T |

|---|---|---|---|

| Number of axes | 5 | ||

| X/Y/Z travel [mm] | 720/910/810 | 1800/1250/1320 | |

| X/Y/Z feed [m/min] | 60/60/60 | 50/50/50 | |

| Max. Table load [kg] | 350 | 2000 | 3200 |

| Maximum component size [mm] | ø700/630 | ø1.800/1.200 | |

| Tool holder | HSK63A (HSK100A) | HSK100A (HSK63A) | HSK100T |

| Tool capacity | 32 (60/90/120) | 40 (60/90/120) | |

| Controls | Siemens, Heidenhain | ||

Typical components

Our HS series is the ideal solution for the production of complex aerospace components. Typical applications include blisks, impellers, engine housings and high-strength structural components made of titanium and superalloys. In addition, the 5-axis horizontal machining center is perfect for wing ribs, stringers, flap tracks and structural frames.

Blisks

Engine housing