Challenges in the machining of small parts

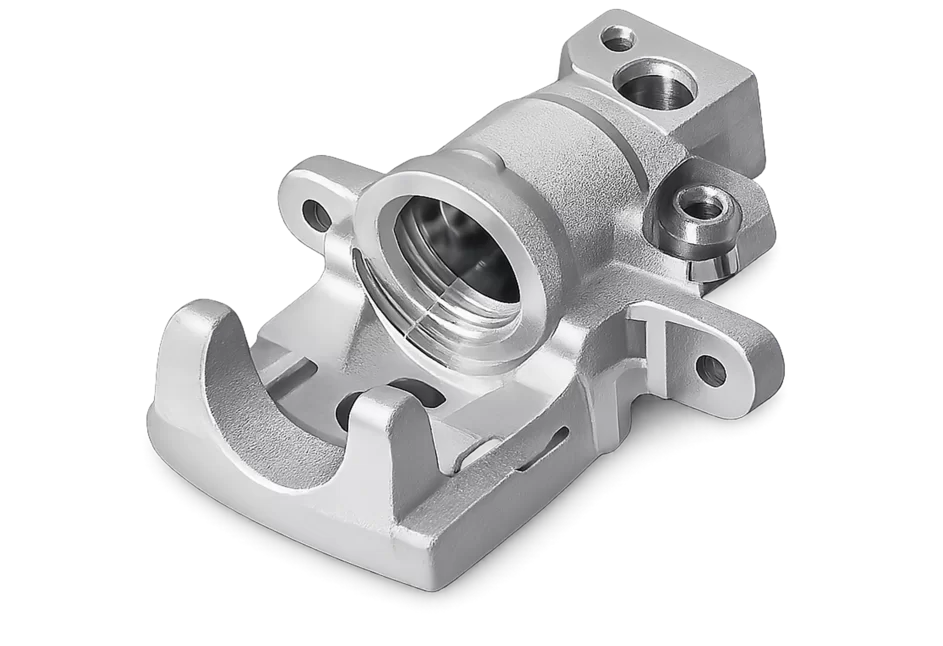

- Diverse component geometries and material requirements call for flexible machine concepts and sophisticated clamping solutions.

- Tight tolerances and high precision: dimensional accuracy and repeatability are crucial for quality and assembly capability, particularly in the aerospace and automotive industries.

- Economical series production: short cycle times, automated processes and high process reliability are essential for large quantities.

Our strengths in the processing of small parts

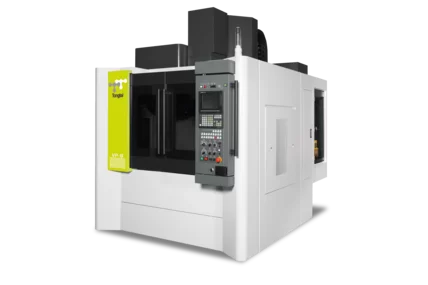

Large machine portfolio

Our machine series offer powerful 3- to 5-axis solutions for the precise machining of a wide range of small parts.

Efficiency for every component size

From tiny precision parts to components up to 1,200 mm in length - we guarantee economical processes with the highest quality.

Modularity for maximum flexibility

Machine configurations with 5th axis as rotary table or pallet changer, individually adaptable to your production requirements.

Automation

Sophisticated automation concepts enable fast part changes, increase productivity and reduce manual intervention.