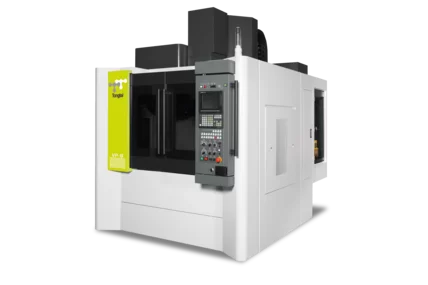

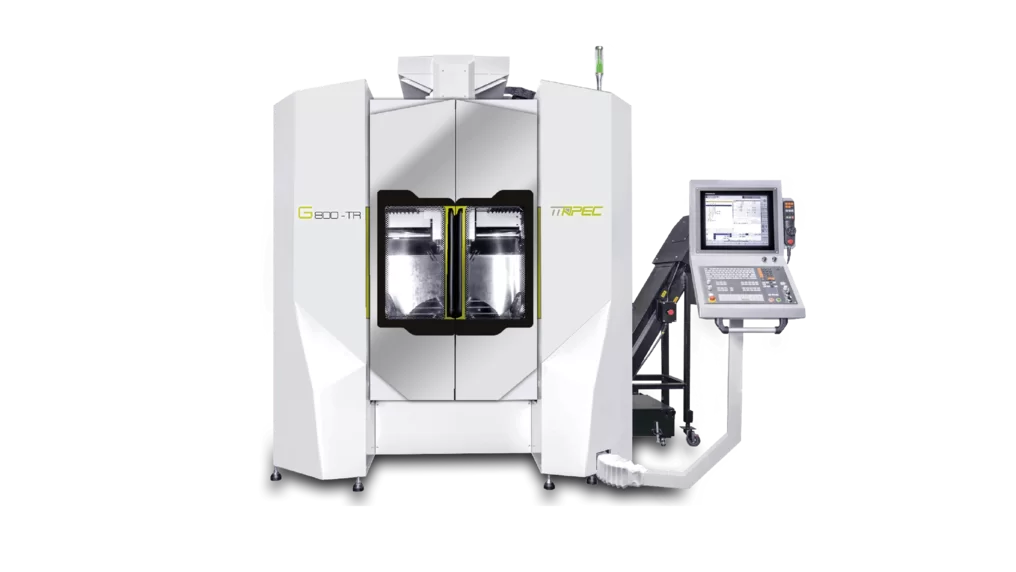

G-Series

Vertical 5-axis gantry machining center

The G800 is a highly dynamic 5-axis machining center in portal design, developed for the simultaneous machining of complex aerospace, automotive and moulded components.

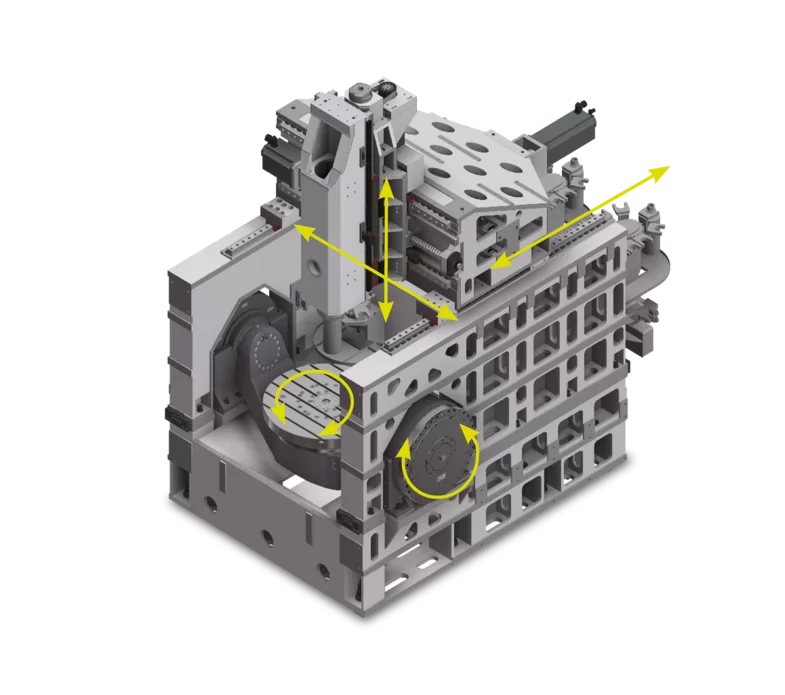

Its gantry structure, the direct drives on the swivel axes and the fully encapsulated design ensure maximum rigidity, surface quality and process reliability, even during high-performance machining.

Technical details:

| Machine model | G800TR | G800T |

|---|---|---|

| Number of axes | 5 | |

| X/Y/Z travel [mm] | 800/830/560 | |

| X/Y/Z feed [m/min] | 48/48/48 | |

| Max. Table load [kg] | 1300 | |

| Maximum component size [mm] | ø900/500 | |

| Tool holder | HSK63A (HSK100A) | HSK63T (HSK100T) |

| Tool capacity | HSK63:32(64) HSK100: 24(60) | |

| Controls | Siemens, Heidenhain | |

Typical components

The G-series is suitable for machining engine rotors, blades, housings, impellers, structural parts made of aluminum or titanium as well as precision and stamping dies. It is ideal for 5-axis milling, high-speed and finishing processes.