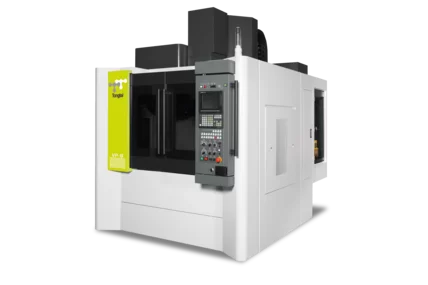

TMV series

Vertical machining center for demanding milling operations

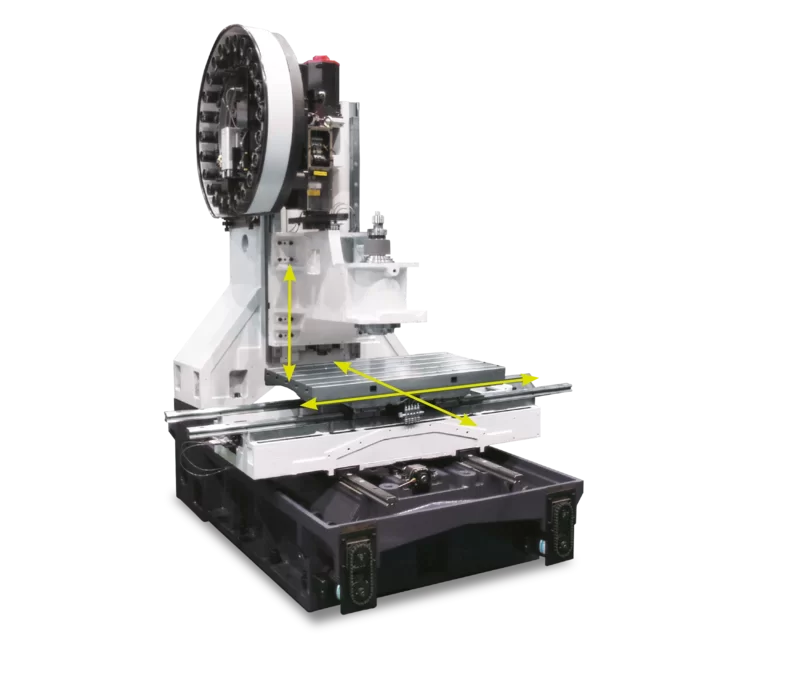

The TMV series is a vertical machining center that has been specially developed for the stable series production of medium-sized to large components. It combines high machining speed, efficient chip handling and a robust machine structure with extensive automation options and additional axes. This makes it ideal for complex milling operations with the highest quality requirements and ideal for use in mass and automated production lines.

Technical details:

| Machine model | TMV 850QII | TMV 1050QII | TMV 1350A | TMV 1600A |

|---|---|---|---|---|

| Number of axes | 3 | |||

| X/Y/Z travel [mm] | 850/600/530 | 1050/600/530 | 1350/750/700 | 1600/800/700 |

| X/Y/Z feed [m/min] | 48/48/48 | 20/20/15 | 15/15/12 | |

| Max. Table load [kg] | 800 | 1300 | 2000 | |

| Maximum component size [mm] | 950/600/630 | 1100/600/630 | 1500/750/700 | 1700/850/700 |

| Tool holder | BBT40 | BBT50 (HSK100) | ||

| Tool capacity | 24 | 24 (32) | 32 (40) | |

| Controls | Siemens, Fanuc | |||

Typical components

Machine parts, fixtures, cast iron and steel components - ideal for precise milling and drilling operations