VP series

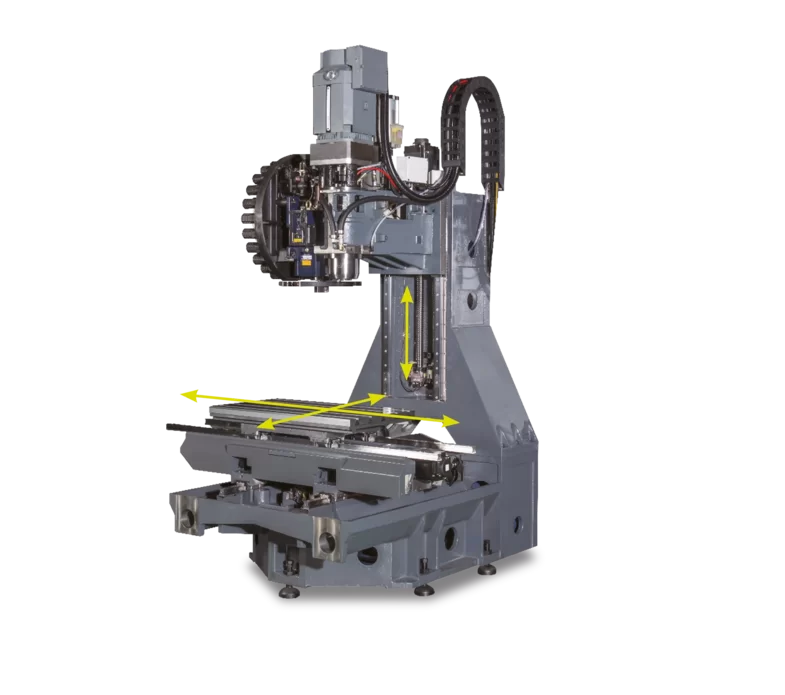

Vertical 3-axis machining center for universal production

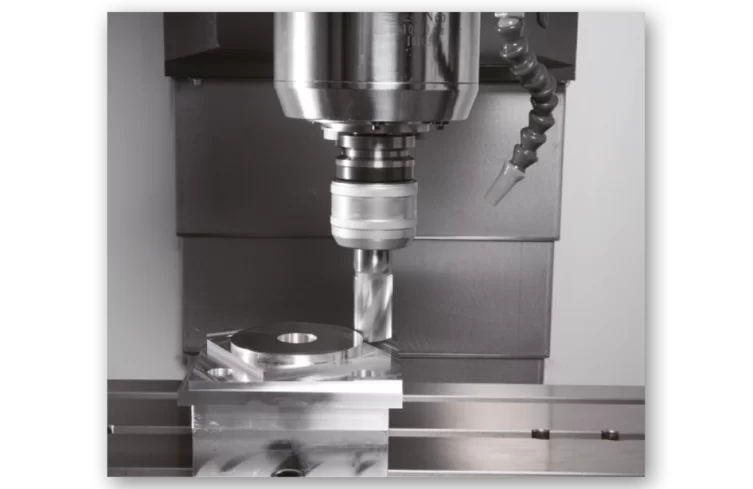

The VP series is a vertical machining center for precise and repeatable 3-axis machining of medium-sized components. Its robust design, high dynamics and ergonomic operation make it ideal for demanding production environments.

Technical details:

| Machine model | VP-8 | VP-10 | VP-12 |

|---|---|---|---|

| Number of axles | 3 | ||

| X/Y/Z travel [mm] | 820/510/535 | 1020/510/600 | 1270/670/710 |

| X/Y/Z feed [m/min] | 48/48/36 | 36/36/36 | 36/36/30 |

| Max. Table load [kg] | 500 | 1300 | |

| Maximum component size [mm] | 900/510/535 | 1070/510/600 | 1350/710/710 |

| Tool holder | BBT-40 | ||

| Tool capacity | 24 (30) | ||

| Controls | Siemens, Fanuc, Mitsubishi | ||