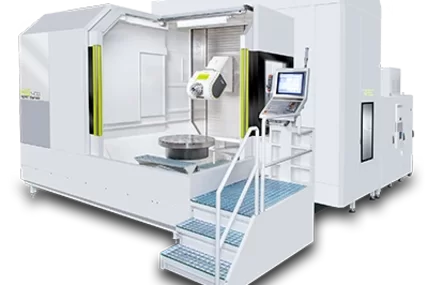

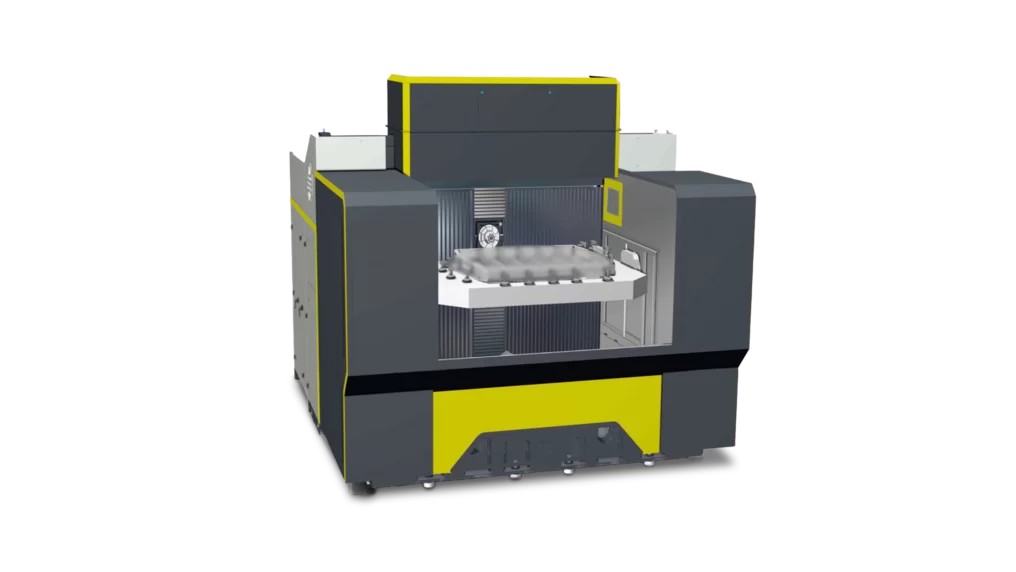

Meteor 3000

Horizontal machining center for large aluminum and cast components

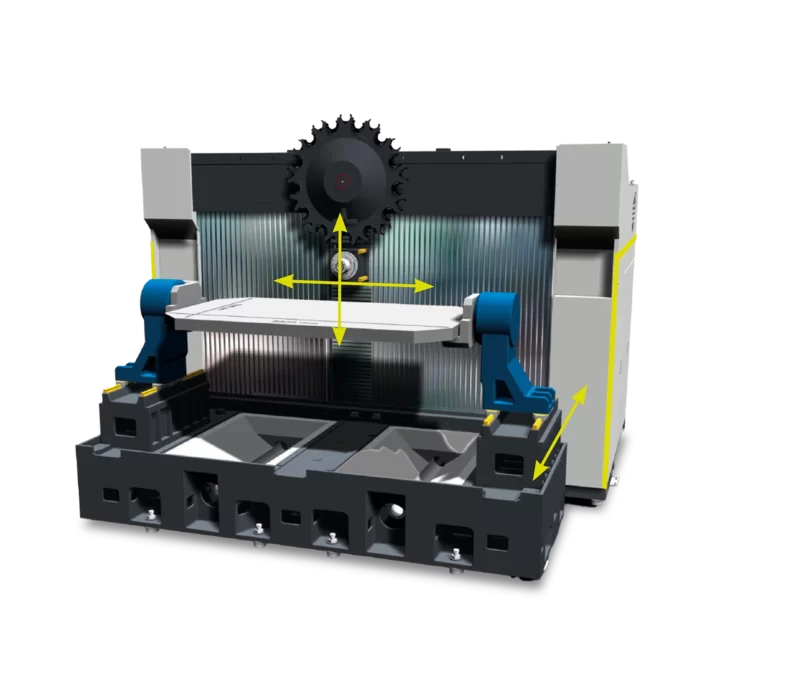

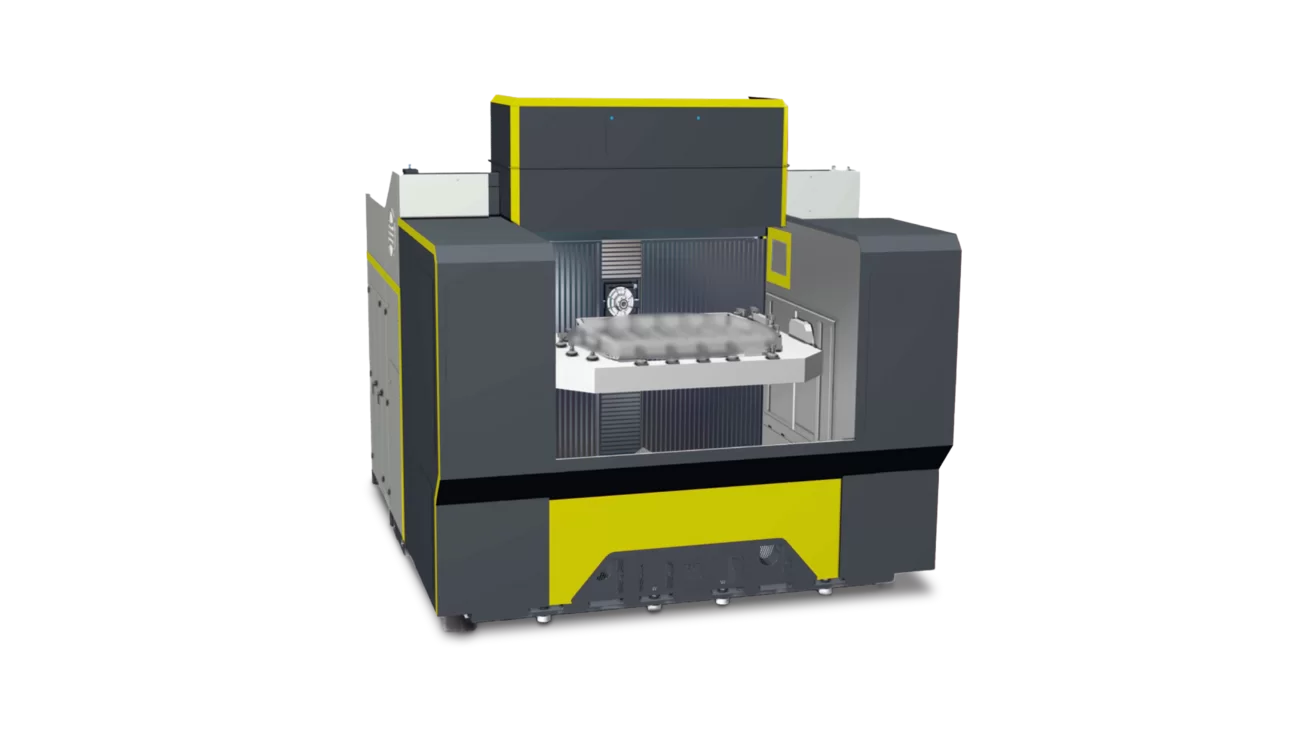

The METEOR 3000 is a flexible 4- or 5-axis horizontal machining center, developed for the highest demands in high-performance production lines, especially for structural and electromobility components. Thanks to the integrated W-axis, the machines are ideal for large-dimensioned workpieces and deep-hole drilling. They offer an energy-efficient solution for machining aluminum and cast materials.

Technical details:

| Machine model | 3000-W | TS3000V-W |

|---|---|---|

| Number of axes | 4 (5) | |

| Number of spindles | 1 | 2 |

| X/Y/Z/W Travel [mm] | 3000/1600/630/630 | |

| X/Y/Z/W feed [m/min] | 80/80/80/80 | |

| Max. Load on A-axis [kg] | 3500 (incl. bridge) | |

| Maximum component size [mm] | 3200/ø2000 | |

| Tool holder | HSK63 | |

| Tool capacity | 29 | 2x29 |

| Controls | Fanuc | |

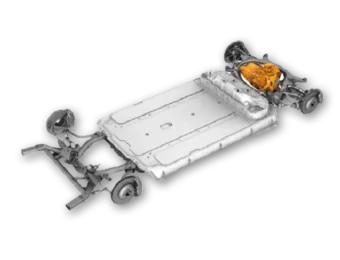

Typical components

The Meteor 3000 is suitable for machining large-dimensioned aluminum or cast components, e.g. structural parts and components for electric vehicles.