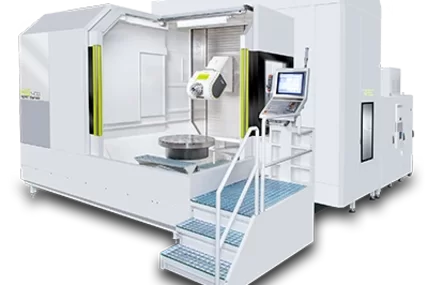

PP2

Horizontal double-spindle machining center for profile machining

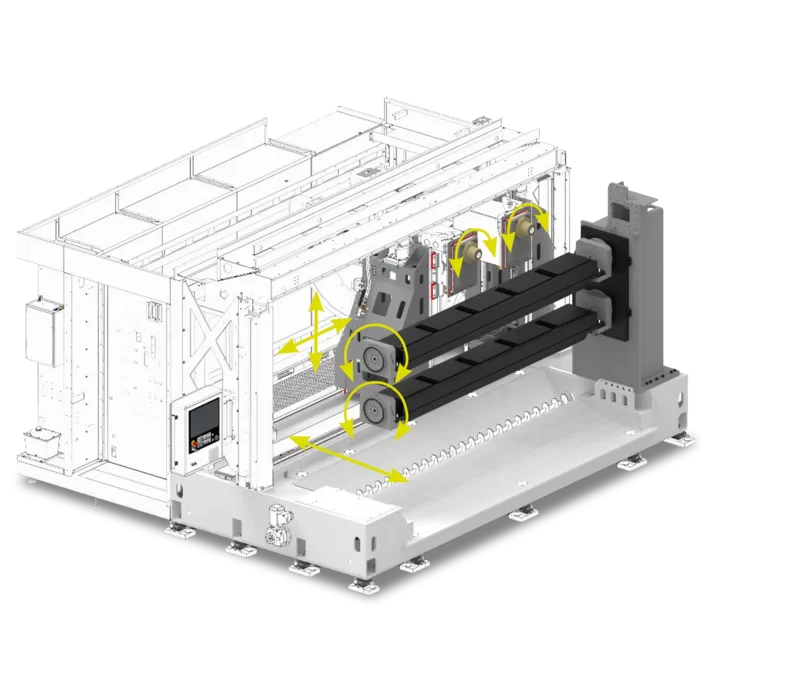

The PP2 is a highly productive machine for processing extruded aluminum profiles. While two processing spindles are working on one processing bridge, the other bridge is loaded and unloaded parallel to production.

Technical details:

| Machine model | PP2 |

|---|---|

| Number of axes | 4 |

| Number of spindles | 2 |

| X/Y/Z travel [mm] | 3200/915/630 |

| X/Y/Z feed [m/min] | 90/60/60 |

| Max. A-axis load [kg] | 3000 (per A-axis) |

| Maximum component size [mm] | 3400/ø560 (per A-axis) |

| Tool holder | HSK63-A |

| Tool capacity | 2 x 29 (2x41, 2x61) |

| Controls | Siemens |

Typical components

The PP2 is ideal for processing extruded profiles such as battery frames, terminal strips, sills or trailer profiles.