Challenges in the machining of structural components

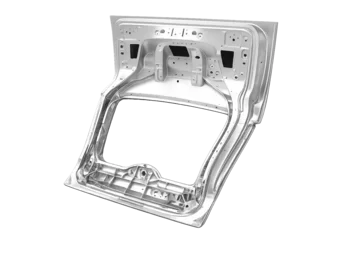

- Large component dimensions: Structural components such as complete vehicle floors, body elements or crash structures have very large dimensions. This places high demands on machine rigidity, workspace, clamping technology and process stability.

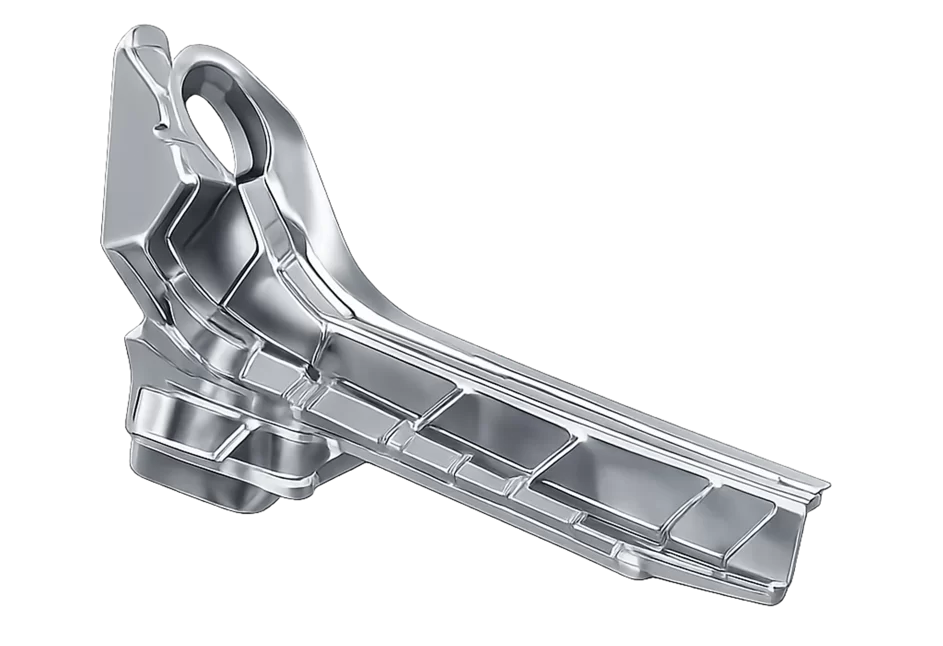

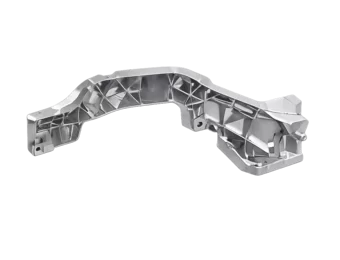

- Complex geometries: The integration of multiple functions in a single component requires high-precision machining of complex shapes and interfaces.

- High precision & repeatability: Tight tolerances are crucial for the accuracy of fit, stability and crash properties of the body.

Our strengths in the processing of structural components

Maximum accessibility

Optimum machining solutions thanks to a 5th axis - optionally as a rotary table or swivel spindle.

Spacious machining centers

Our machines enable the processing of large-format structural components up to 3.2 x 1.8 meters.

Double-spindle machining possible

Two independent spindles increase efficiency through simultaneous machining.

Automation solutions

Integrated systems for optimized material flow and component handling with minimal space requirements.