Challenges in profile processing

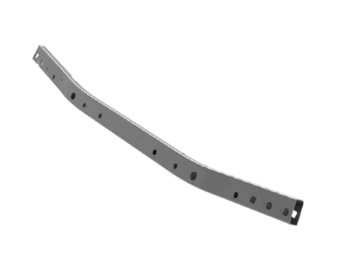

- Versatile profile geometries: Different profiles such as side, front or rear profiles require flexible clamping fixtures.

- High precision requirements: Exact machining despite tolerances from the extrusion process.

- Optimization of non-productive times: With short machining times, non-productive times must be optimized as much as possible by loading and unloading parallel to machining time.

Our strengths in profile processing

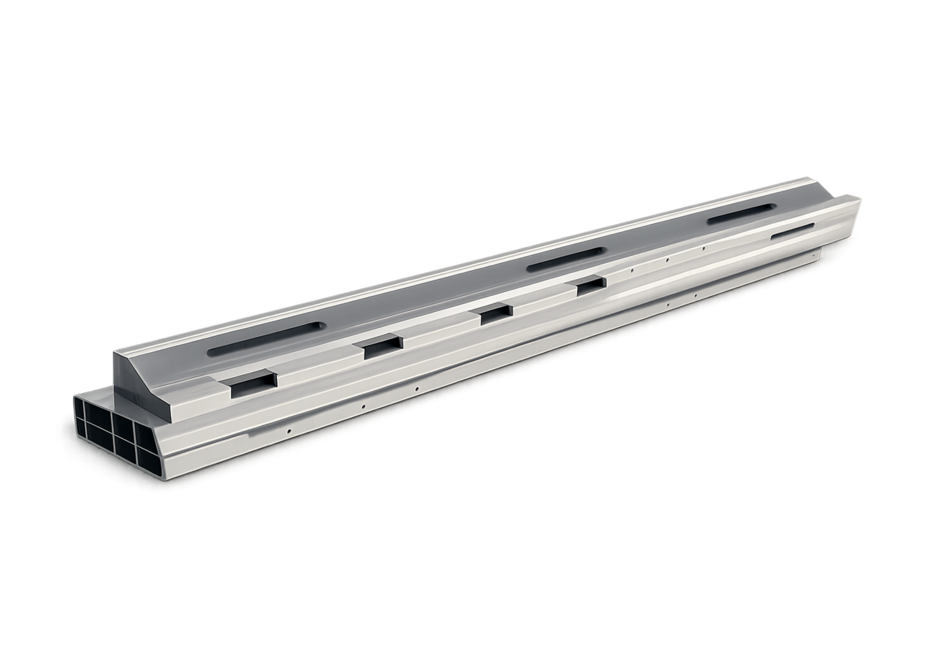

Universal clamping devices

Clamp different profiles securely without machine changeover - for more flexibility and shorter set-up times.

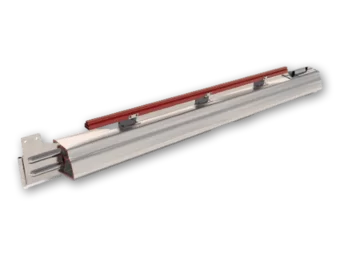

Precision measurement

Probes or lasers measure geometries before machining - for maximum accuracy and minimum rejects.

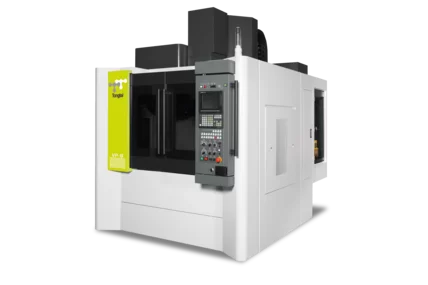

Single-spindle machining

for smaller profiles or series

Double or four-spindle machining

for maximum efficiency and speed in series production.