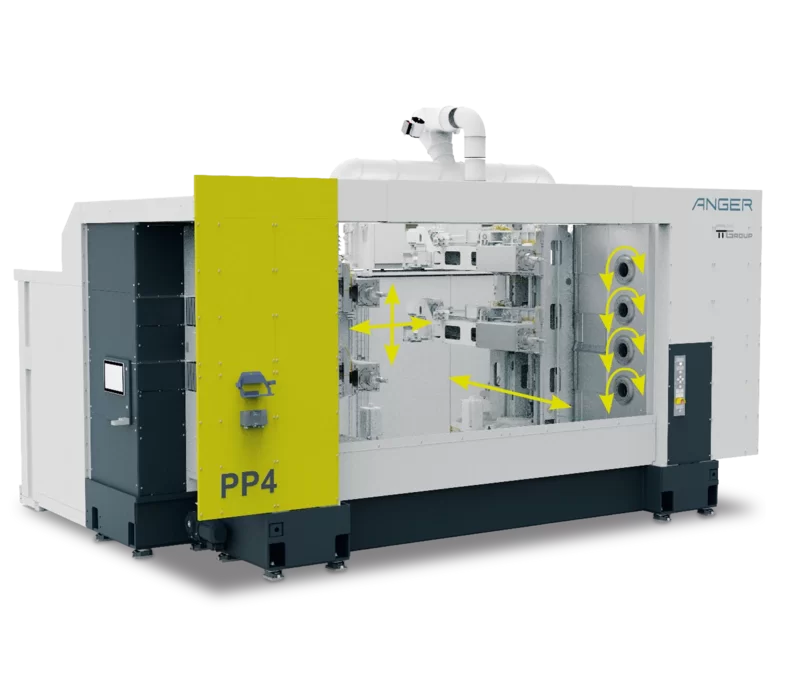

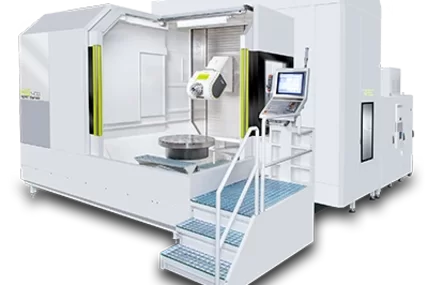

PP4

Horizontal four-spindle machining center for maximum efficiency in profile machining

The PP4 is the most productive solution for processing extruded aluminum profiles. While four processing spindles work on two processing bridges, the other two bridges are loaded and unloaded in parallel. For example, machining takes place on bridges 1 and 3 and loading takes place on bridges 2 and 4.

Technical details:

| Machine model | PP4 |

|---|---|

| Number of axes | 4 |

| Number of spindles | 4 |

| X/Y/Z travel [mm] | 3200/390 (810 over both bridges)/630 |

| X/Y/Z feed [m/min] | 100/90/60 |

| Max. A-axis load [kg] | 2000 (per A-axis) |

| Maximum component size [mm] | 3400/ø420 (per A-axis) |

| Tool holder | HSK63-A |

| Tool capacity | 20 |

| Controls | Siemens |

Typical components

The PP4 is perfect for the efficient processing of extruded profiles such as battery frames, terminal strips, sills or trailer profiles.