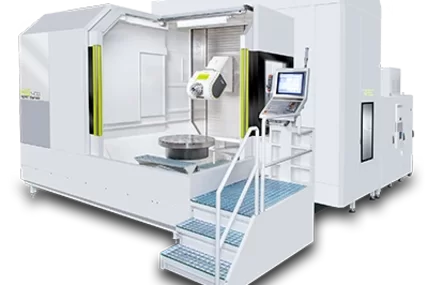

SP2-D

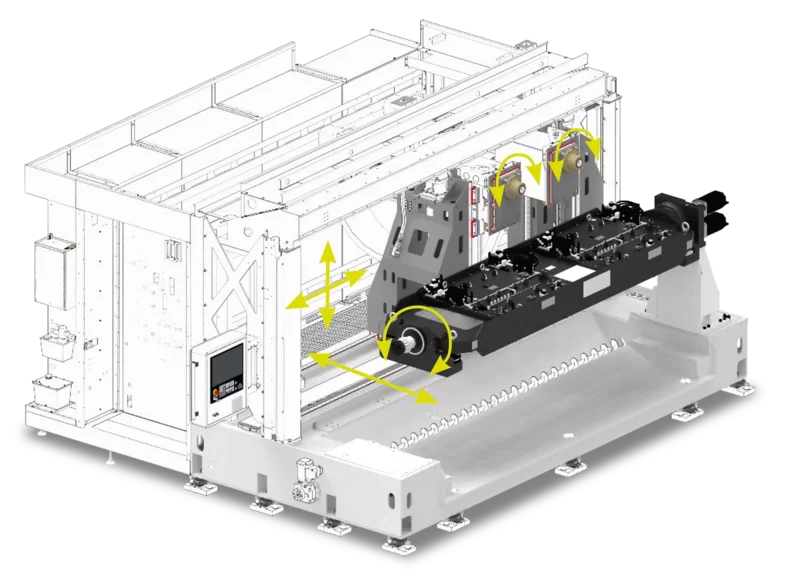

5-axis horizontal machining center

The SP series is a flexible machining centre for

4- or 5-axis double machining of large-volume components.

The large work area allows maximum flexibility in

process design and machining. Two independent spindles

machine either two components synchronously or simultaneously a

large component with a maximum length of 3,600 mm and

an interference circle of 1,200 mm.

Technical details:

| Machine model | Sp2-D |

|---|---|

| X/Y/Z travel [mm] | 3.200/915/630 |

| Number of axes | 4 (5) |

| X/Y/Z feed [m/min] | 90/60/60 |

| Max. Load on A-axis | 3.000 |

| Maximum component size [mm] | 3.400/Ø1.200 |

| Tool holder | HSK63A |

| Tool capacity | 2 x 29 (2x41, 2x61) |

| Controls | Siemens controls |

Typical components

Our SP2-D is the ideal solution for the production of structural components or profiles.

Battery trays

Structural components