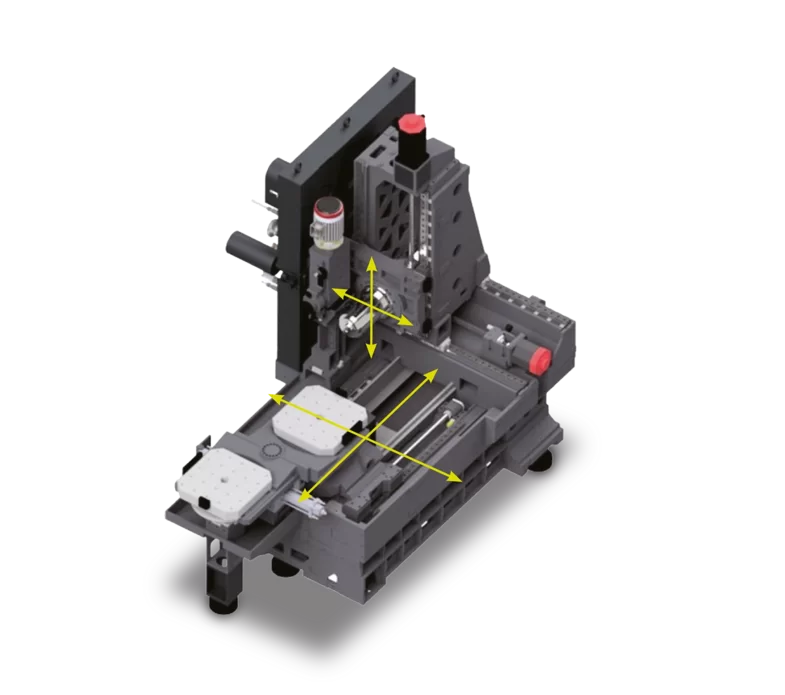

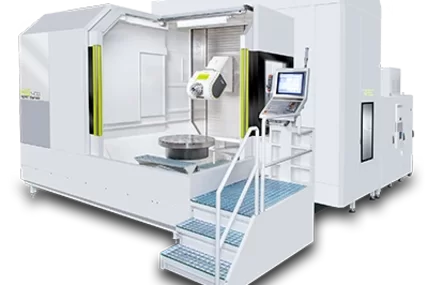

THA series

Horizontal 4-axis machining center

The THA series is a compact horizontal machining center for the economical series machining of aluminium and cast components. With a powerful direct drive spindle, an optional pallet changer and high dynamics with a small footprint, the machine is ideal for production lines with high quantities and short cycle times.

Technical details:

| Machine model | THA-4000(p) | THA-5000(p) |

|---|---|---|

| Number of axes | 4 | |

| X/Y/Z travel [mm] | 610/610/610 | 730/730/830 |

| X/Y/Z feed [m/min] | 10/10/10 | |

| Max. Table load [kg] | 400 | 500 |

| Maximum component size [mm] | ø630/800 | ø800/1000 |

| Tool holder | BBT-40 (HSK63) | |

| Tool capacity | 40/60/90/120/240 | 40(60) |

| Controls | Siemens, Fanuc | |

Typical components

Aluminum components and cast elements such as differential housings, brake calipers, valve housings - suitable for face milling, drilling, tapping and combination machining