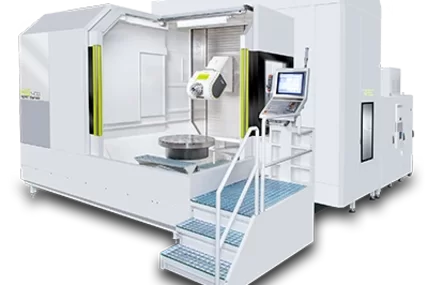

Meteor 1500

Horizontal machining center for complex large components

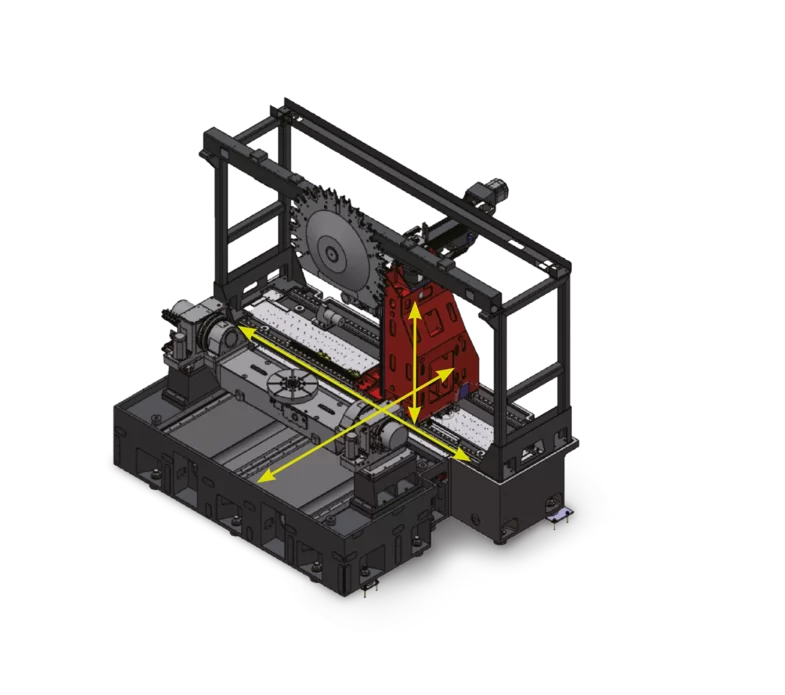

The M1500 is a horizontal all-rounder for the precise machining of medium-sized to large structural components - particularly in the automotive and aerospace industries. With a linear-driven X-axis, optional B-axis, powerful spindles and high spindle speed (up to 18,000 min-¹), it offers maximum productivity and flexibility for demanding machining processes.

Technical details:

| Machine model | M1500 (A63) | M1500 (A100) |

|---|---|---|

| Number of axes | 4 (5) | |

| X/Y/Z travel [mm] | 1600/900/630 | 1550/800/630 |

| X/Y/Z feed [m/min] | 90/80/80 | 70/60/80 |

| Max. Load on A-axis [kg] | 500 | 800 |

| Maximum component size [mm] | 1600/ø1.500 | |

| Tool holder | HSK-A63 | HSK-A100 |

| Tool capacity | 29 | 26 (26+26) |

| Controls | Siemens, Fanuc | |

Typical components

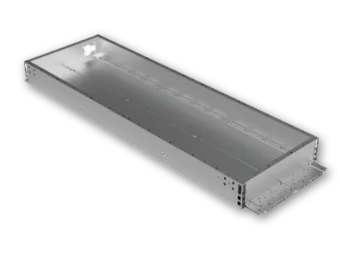

The M1500 is suitable for structural components, subframes, carrier systems, battery frames and extruded profiles, particularly for applications in the automotive and aerospace industries.

Suitable for workpieces with a large swivel range and high metal removal rates.