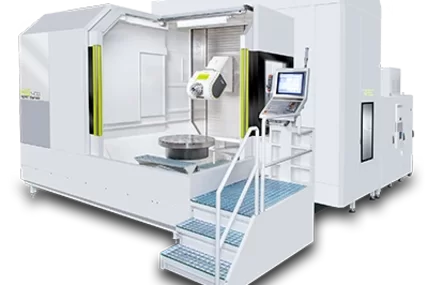

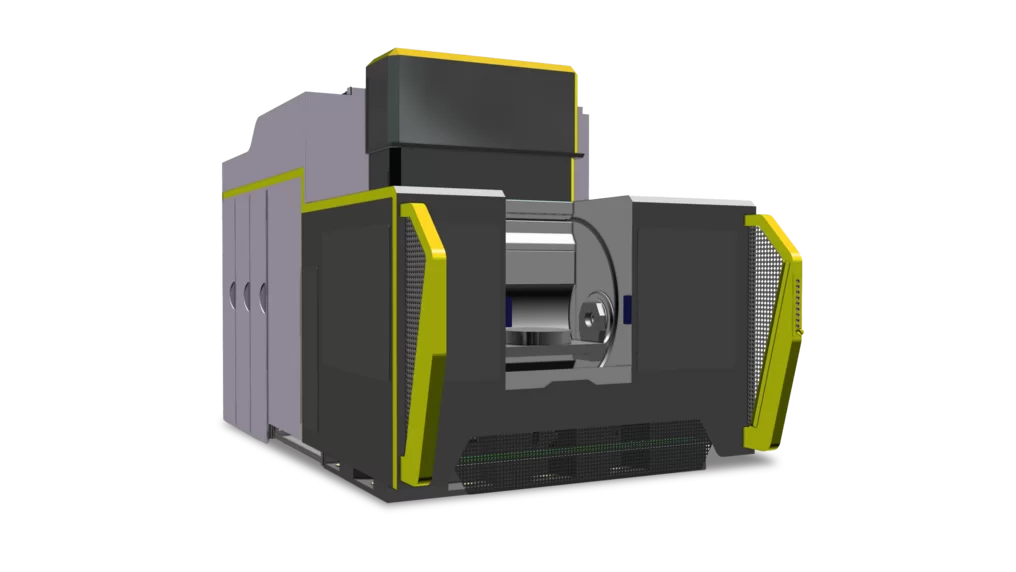

Meteor 630

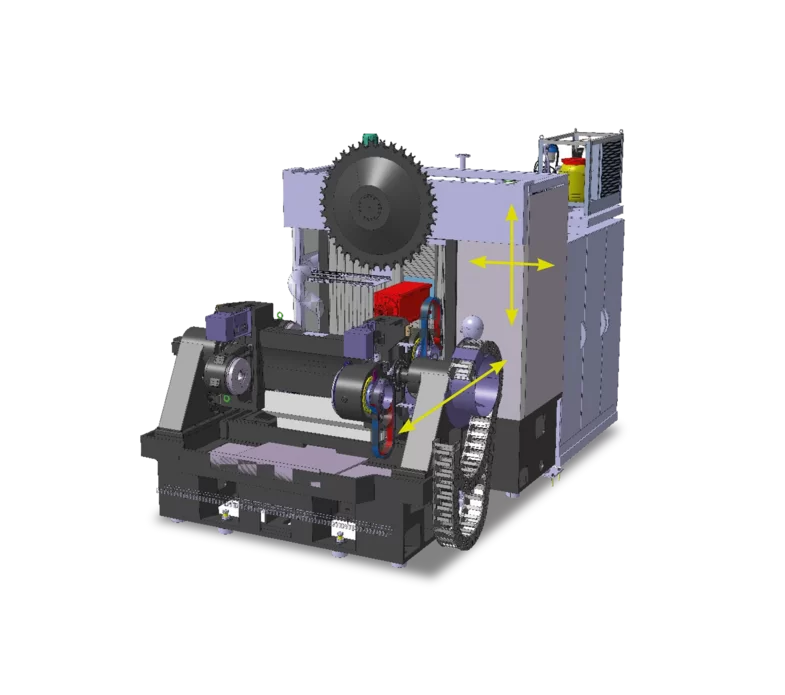

Horizontal 4/5-axis machining center

The METEOR 630 is a 4- or 5-axis horizontal machining center that has been specially developed for high-performance aluminium machining in automated production lines - particularly in the automotive industry. With short cycle times, high dynamics and an optional pallet changer, it is designed for maximum productivity in a compact design.

Technical details:

| Machine model | 630 | 630(P) |

|---|---|---|

| Number of axes | 4 (5) | |

| X/Y/Z travel [mm] | 630/ 630/ 630 | |

| X/Y/Z feed [m/min] | 90/80/80 | |

| Max. Load on A-axis [kg] | 2000 | |

| Maximum component size [mm] | ø800/960 | |

| Tool holder | HSK-A63 | |

| Tool capacity | 34 | |

| Controls | Siemens, Fanuc | |

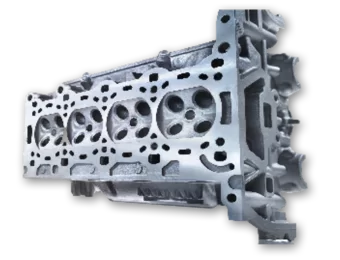

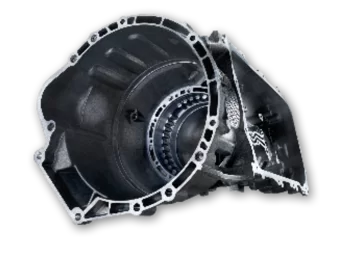

Typical components

The Meteor 630 is suitable for machining aluminum components from the automotive sector, e.g. transmission parts, valve housings, structural components.