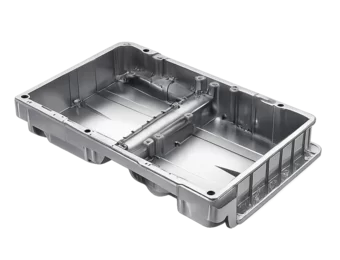

Challenges of battery tray machining

- Challenging clamping technology for cast trays: Complex geometries, tight tolerances and thin-walled structures require a precise clamping system. The perfect balance between optimum clamping forces, effective vibration damping and minimal deformation is crucial. At the same time, the clamping solution must be flexible enough to implement OP10 and OP20 in a single fixture, for example.

- Precise fitting dimensions & sealing surfaces for reliable sealing of the battery pack.

- Fine surface structures to optimize heat dissipation and assembly.

- High process reliability & repeat accuracy for consistent quality in series production.

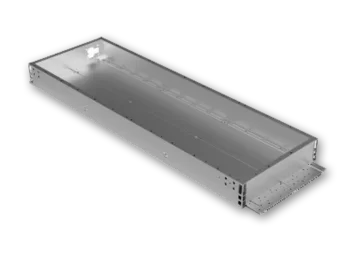

Universal clamping fixtures

Can be used flexibly for different profile geometries - without any time-consuming retooling.

Maximum flexibility for your ramp-up curve

Flexible single-spindle machines adapt dynamically to your requirements, while double-spindle systems enable the shortest cycle times and maximum productivity thanks to simultaneous machining.

Fitting dimensions and precision

Precise machining for tight tolerances, exact fitting dimensions and reliable sealing surfaces in series production.

Individual technical elaboration & cycle time reports

Precise analyses for your specific component for optimal machine and process design.