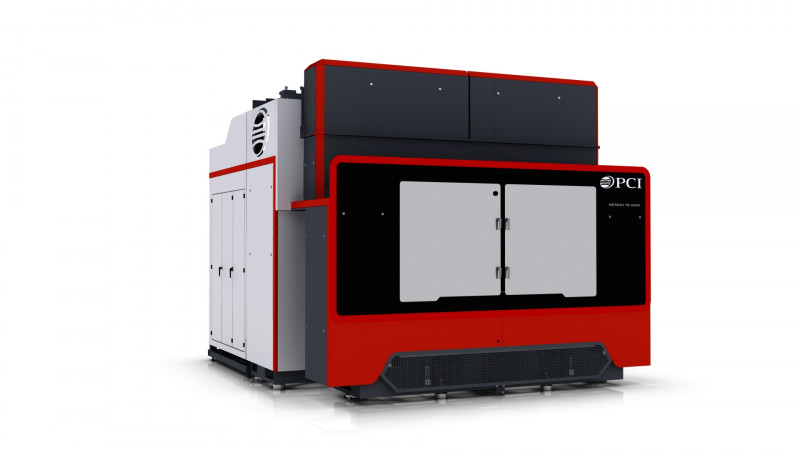

METEOR TS630V

The METEOR TS630V machining center is designed for the highest demands of high-performance production lines and is available in 4 or 5 axes. The adjustable spindle distance offers maximum flexibility. For customers who require short cycle times and loading/unloading times, the machine can be optionally equipped with a pallet changer.

Technical Details

| Number of axis | 4 or 5 axes |

| Process area | 630-1260/630/630 mm |

| Maximum component size L/W/H | ø 800 x 2175 |

| Axis speed X/Y/Z | 90/80/80 m/min |

| Spindles | 2 |

| Machine size LxWxH | 4195 x 2390 x 3419 mm |

Downloads

You have questions about our machines?

We will be happy to advise you and develop an individual solution together with you.

Other machines at a glance

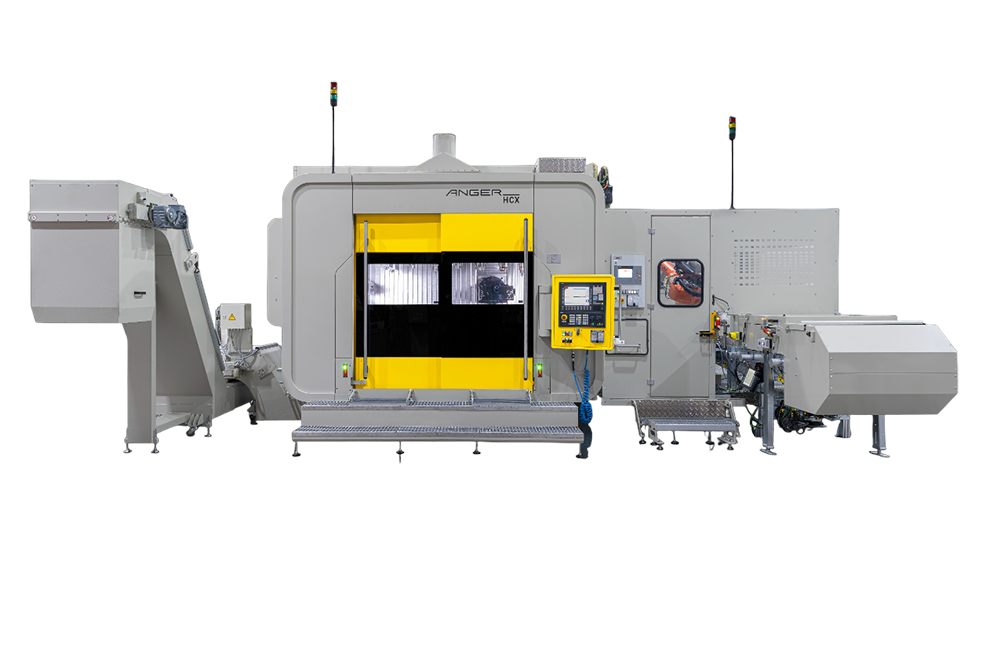

HCX

The ANGER HCX Turn Key systems are specifically designed to meet the needs of the customers. The plant is designed, constructed and automated according to the specific parts. As a result, the highly productive HCX systems achieve the shortest cycle times with the highest accuracy. These are highly productive plants with maximum output rates. Depending ... Read more

Learn more

SP2-A

The ANGER SP2-A machine is the most efficient solution for processing extruded aluminum profiles. While both processing spindles are working on one processing bridge, loading and unloading takes place in parallel on the second bridge. The second clamping bridge swivels into the machining area in less than 2 seconds. Each tool is then machined alternately ... Read more

Learn more

SP2-D

The ANGER SP2-D machine is a flexible machining center for 4- or 5-axis double machining of large-volume components. The two processing units can process one component or different parts independently of each other. The large working area allows you maximum flexibility in process design and machining. With a clamping bridge of approx. 3,600mm length and ... Read more

Learn moreCustomer support